In today’s stone industry, efficiency, precision, and sustainability define success. Among cutting technologies, the multi-wire saw machine has become the preferred choice for quarries and processing factories worldwide.

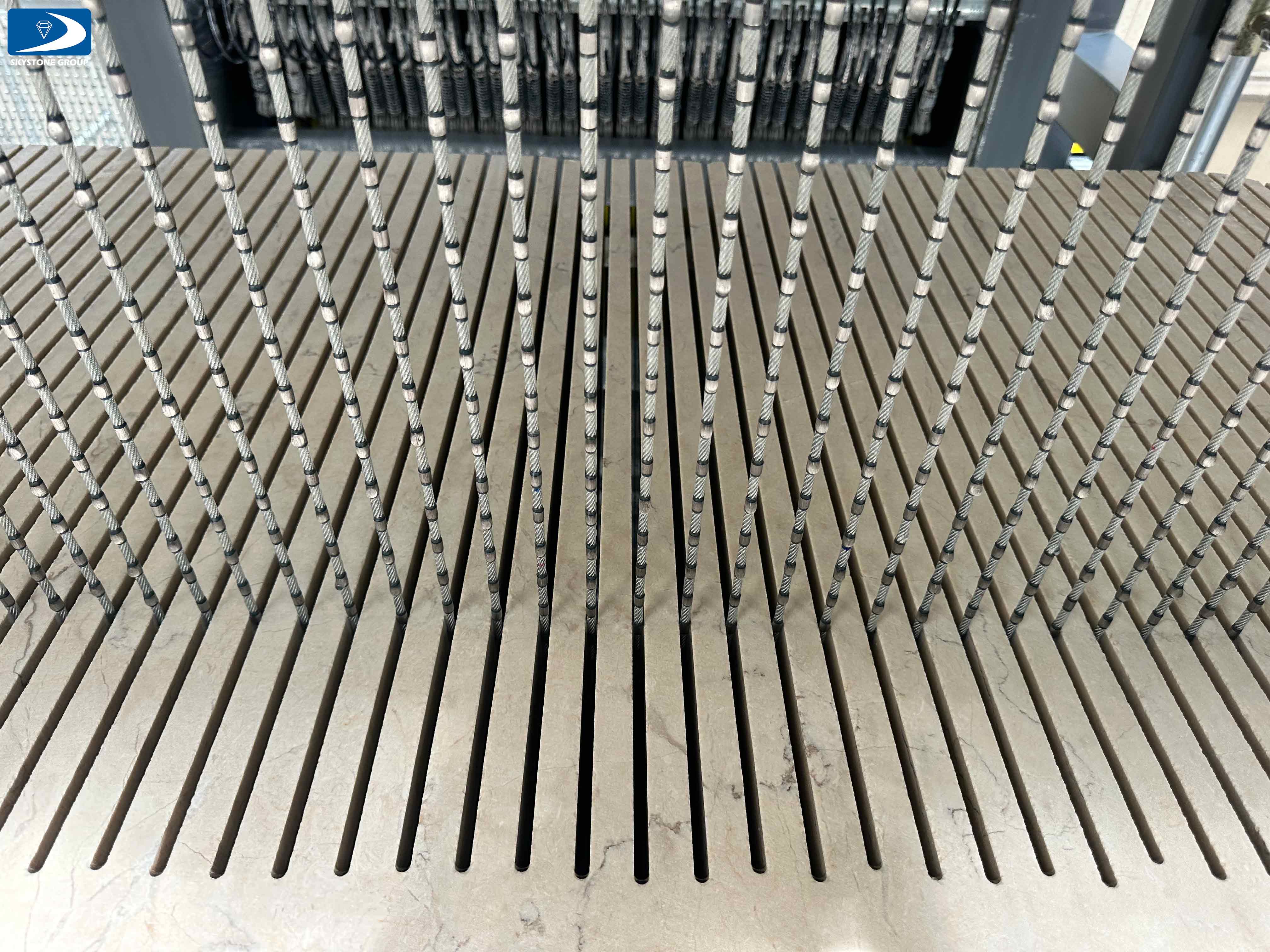

A multi-wire saw cuts multiple slabs simultaneously from one block—up to dozens of wires working together—delivering more slabs per block, faster turnaround, and lower labor costs than traditional single-wire or gang-saw systems.

Precise control and uniform wire tension produce smoother, cleaner cuts that need minimal polishing, saving downstream time and expense.

Ultra-thin diamond wires (4.3 mm / 4.8 mm) reduce kerf loss and power draw, delivering greener cutting that meets modern sustainability targets.

Skystone multi-wire saws handle granite, marble, quartz and engineered stone. Adjustable wire spacing covers any slab thickness, while precision electroplated & sintered diamond wires ensure long life and stable cutting.

From Italy to India, Brazil to China, Skystone systems deliver proven reliability. Continuous innovation in wire design and machine control keeps clients ahead in productivity and quality.

Choosing a Skystone multi-wire saw machine and multi-wire means choosing efficiency, precision and sustainability. As the industry evolves, we remain committed to advanced wire-cutting technologies that turn every block into better results.