In stone cutting operations—especially with multi-wire saw machines—wire breakage remains a costly and frustrating problem. With the growing demand for efficiency and precision, the diamond multi-wire saw has undergone significant technological advancements. This article explores the most up-to-date innovations in wire design and machine compatibility that help reduce wire breakage and improve overall cutting performance.

The latest generation of diamond wire beads for multi-wire saw machines uses a refined matrix composition. This not only enhances diamond retention but also ensures consistent exposure of fresh diamonds during cutting. The result? Smoother operation, less heat generation, and fewer stress points that could lead to premature wire failure.

High-tensile steel wires with improved torsional strength are being adopted to handle longer cutting cycles and higher loads. For multi-wire saw applications, Skystone’s updated core wire materials minimize the risk of internal wire fatigue and breakage, especially under high-speed operation.

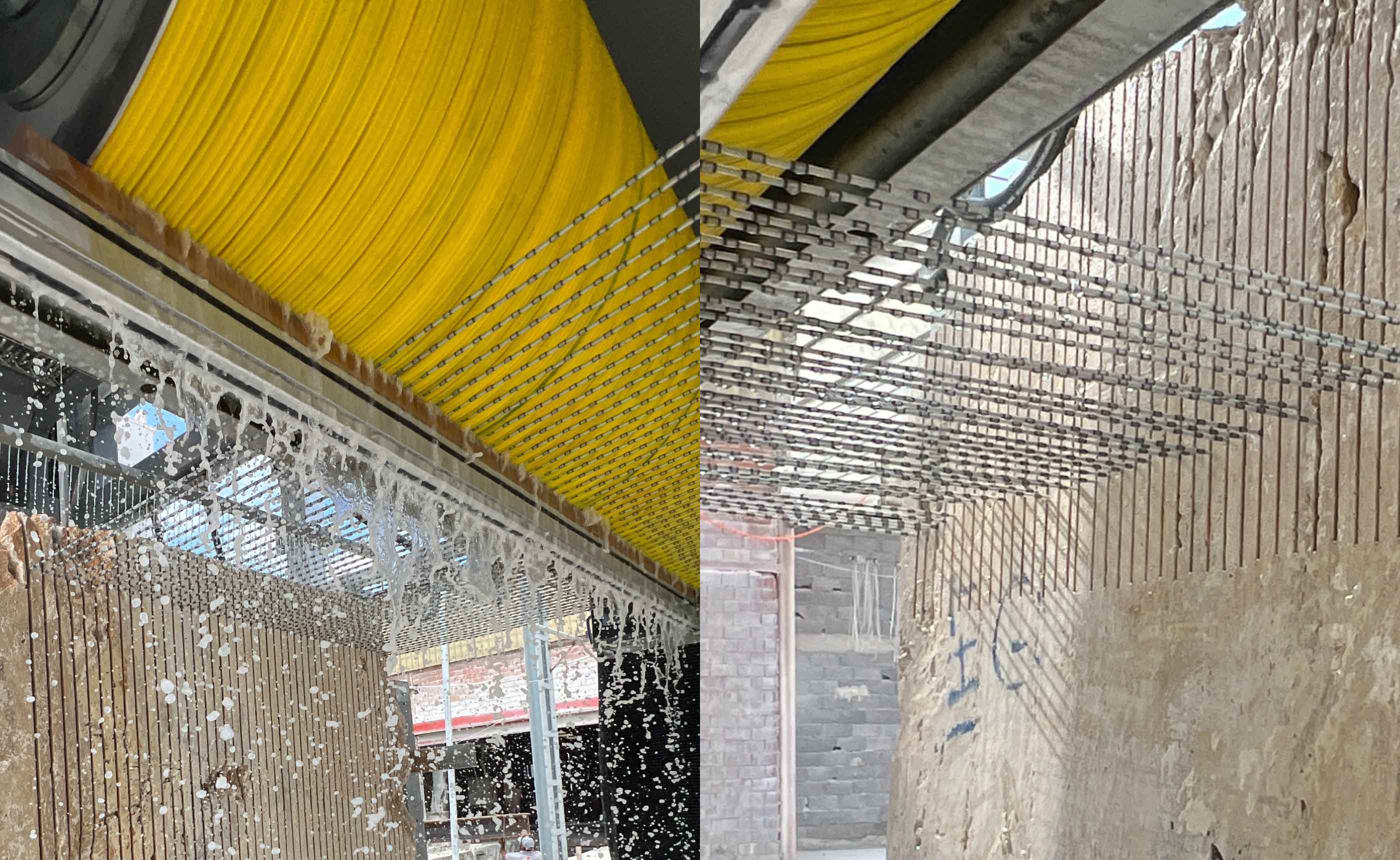

Improved injection techniques allow for more uniform bonding between the beads and the wire core. This reduces vibration in multi-wire saw cutting and allows the beads to stay firmly in place during cutting—key to avoiding localized wear and sudden breaks.

Modern diamond wires are now designed to match the specific tension and speed settings of multi-wire saw machines. When matched correctly, the system operates with lower internal stress, significantly extending the life of the wire.

Some high-end multi-wire saw systems now include real-time monitoring of cutting parameters and auto-tensioning systems. These help maintain consistent pressure and quickly detect any anomalies that could cause wire damage—allowing preventive action before breakage occurs.

Minimizing wire breakage in multi-wire saw operations is not just about using better wire—it’s about a holistic system that includes machine compatibility, precise tensioning, improved materials, and smarter operations. Skystone continues to lead in this field, offering diamond multi-wire solutions that not only cut faster but also last longer—helping our clients reduce downtime and improve cutting ROI.